LP TopNotch Guard 350 - Oriented Strand Board (OSB)

ENGINEERED TO PERFORM

From squeak-free floors to solid wall and roof sheathing oriented strand board (OSB) is shaping how the world builds. OSB is engineered for strength and designed for a variety of applications. OSB is a proven performer for many residential and nonresidential applications. Its high performance capabilities make OSB ideal for diverse markets, including material-handling applications, the structural insulated panel industry, do-it-yourself projects, wood I-joist products, and industrial applications such as furniture and trailer liners.

This product Guide from APA describes OSB's features, uses, quality assurance, and performance. APA began providing a quality assurance program for OSB in 1981 and has led the engineered wood industry in OSB research and quality program ever since. The APA trademarks is the manufacturer's assurance to you that the OSB panel is produced to APA's stringent requirements as well as to U.S. and Canadian standard requirements. The APA trademark also assures you that an OSB manufacturer is committed to quality.

PRODUCT FEATURES

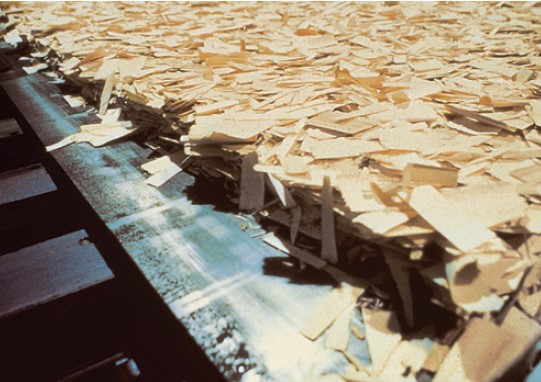

OSB is made from real wood

OSB is manufactured in a cross-oriented pattern similar to plywood to create a strong, stiff structural panel. OSB is composed of thin rectangular-shaped wood strands arranged in layers at right angles to one another, which are laid up into mats that form a panel. OSB is bonded with water-resistant adhesives. Most panels are also treated with a sealant on the panel edges to guard against moisture penetration during shipment. As an added feature, panels are often textured on at least one side to provide a slip-resistant surface.

OSB uses the wood resource very efficiently, in part because sheathing panels can be made using smaller, younger fast-growing smaller, younger fast-growing tree species, such as aspen and southern yellow pine. Plus, about 85-90 percent of a log can be used to make high quality structural panels, and the remainder-bark, saw trim, and saw dust - can be converted in to energy, pulp chips or bark dust.

OSB manufacture

In the first phase of OSB manufacture, logs are debarked and cut to a uniform length. The logs are then turned into strands. The strands are dried with heat in a large rotating drum which is screened to grade for strands that are the correct size. Liquid or powder adhesive is applied to the dried strands and then transported in layers on a conveyor system to a forming line, where the layers are cross-oriented into mats. Face layer strands generally run along the panel, while core layer strands are randomly oriented or run across the panel. The mats are trimmed to a workable size and then moved to a press where the wood strands and adhesive are bonded together under heat and pressure to create a structural panel. Finally, the panels are cut to size. panels can be manufactured in many sizes simply by altering the cutting pattern.

OSB is engineered to perform

Nearly four decades of laboratory tests and use in the field have proven that OSB is an excellent performer. Performance begins when the panel leaves the manufacturer. The panels remain flat and square during storage and transportation, so they arrive at the jobsite flat and easy to install; tongue-and-groove effortlessly fit together. Relative to their strength, OSB panels are light in weight and easy to handle and install. Frequently, the panels are textured or splatter-coated on one side to increase traction on the panel surface. This is especially useful when the panels are used for roof sheathing, because the textured surface provides better footing for workers. OSB is designed to withstand exposure to the weather during construction.

QUALITY ASSURANCE

OSB panels that bear the APA trademark are manufactured under APA's rigorous quality assurance program, and are recognized by the U.S. and Canadian building codes, as well as many international building codes. Each panel is 'performance rated', which means the panel meets the performance requirements necessary for its end-use applications. Download brochure here to read more

OSB APPLICATIONS AND COMMON SIZES

OSB is most commonly used for traditional applications such as sheathing for roofs and walls, subfloors, and single-layer flooring. Its superior performance has allowed OSB to gain popularity in a variety of other areas, including structural insulated panels, the webs for woods I-joists, materials-handling applications, furniture, and a variety of do-it-yourself projects.

OSB panels manufactured in North America are typically 4X8 feet in size. Metric panel sizes are also available from some manufacturers in 1.25X2.50 metres. Panels for use as exterior siding are also available in narrow lap widths of 6inches (152mm) or 8inches (203mm), and 16 foot (4.88m) lengths. Because OSB is typically manufactured in large sizes, many manufacturers can custom-make panels in almost ant size by simply altering the cutting pattern. Most OSB manufacturers make oversized panels, up to 8X24 feet, which are typically used for panelized roof and wall systems, facers for structural insulated panels (SIPs), or modular floors. In operations where oversized panels can be handled, they provide the advantage of reducing the total number of panels required to do job, and thus speed installation time and reduce construction cost.

OSB can be manufactured with square edges or with tongue-and-groove edges. Panel surface treatments may include texturing or sanding. Overlaid OSB for use as exterior siding also may be surface textured or grooved. See more details in product guide on downloads page

Download Brochures below for more info

Performance claims

OSB withstands rain onsite, ideal for floors

PASS Certification

Minor variation form - Product substitution

(Untreated OSB data sheet - Click & Download)

(Click & Download)