Tricoya Panels for Exterior Applications

Common Applications

Outdoor kitchens, window and door components, door skins, trim, façade cladding, fascia/soffit panels and other secondary exterior applications, wet interiors that include wall linings in swimming pools, bathrooms, changing rooms, signage, specialty furniture including lockers, cubicles, chairs & tables, play frames, tree houses & exterior composite furniture, sound barriers.

High performance MDF panels

Tricoya® is a completely new, high performance MDF panel product. It demonstrates outstanding durability and dimensional stability in the most extreme and challenging environments – both exterior as well as interior, wet and high moisture applications. The product uses proprietary acetylated wood technology and a modified MDF manufacturing process to create a wood panel product with outstanding durability and stability.

Tricoya® was developed by challenging the most fundamental reason for wood swelling: water absorption onto hygroscopic wood fibres due to the presence of hydroxyl groups. The hydroxyl groups (water loving sites) can bind or release water molecules causing wood to swell or shrink.

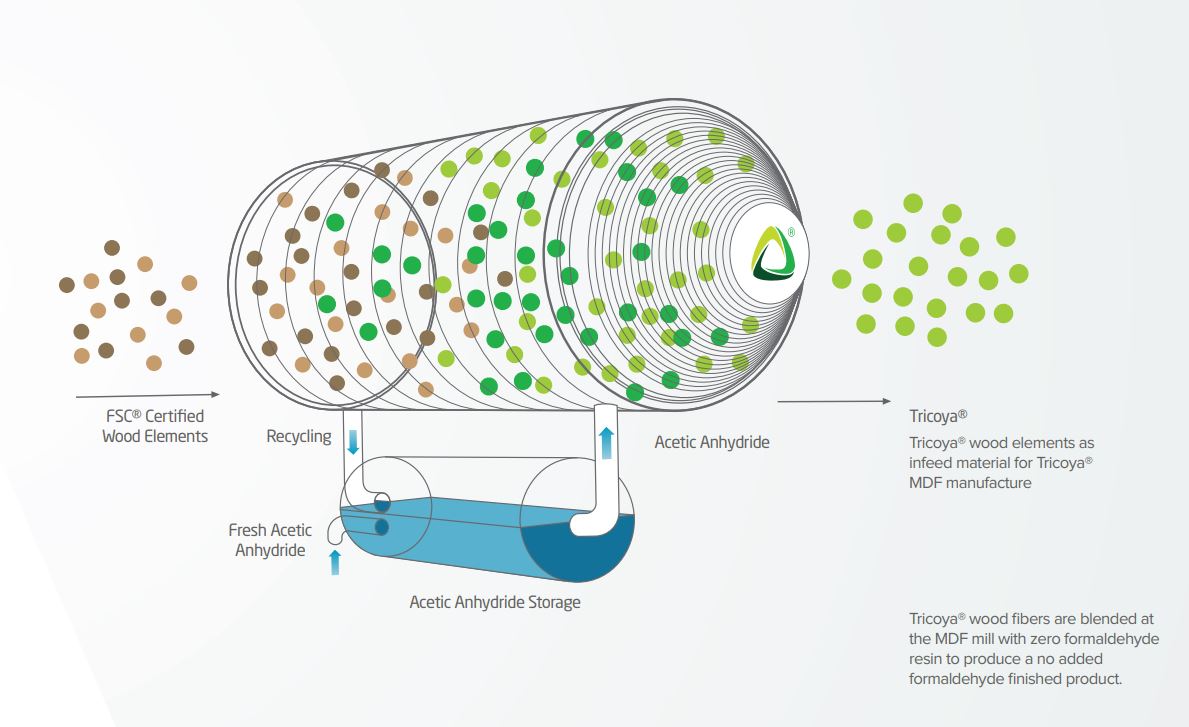

Acetylation is a revolutionary sustainable process which has been proven on Accoya® solid wood since 2007, and increases the number of naturally occurring hydrophobicacetyl groups in the wood cells using acetic anhydride.The process exchanges the hydroxyl groups (chemical formula: -OH) with acetyl groups (chemical formula: -COCH3) preventing water absorption at these sites, and thus enhancing the dimensional stability and durability of the wood.

Apart from creating exceptional dimensional stability, the process enables Tricoya® to achieve class1 durability, leading to resistance to biological decay which exceeds Spotted Gum and Western Red Cedar in Australian fungal decay testing. Termite resistance has also been proven to exceed Spotted Gum, Western Red Cedar, Merbau and PNG Rosewood in extended field trials against Mastotermes in Humpty Doo, Northern Territory.

Tricoya® offers a solution for specifiers and consumers in environments of wet, high humidity or fully weather exposed applications to deliver superior performance in a versatile large panel form. Critical to practical and successful application, there is no requirement in the Tricoya® panel warranty to coat end cuts or drill holes which are exposed to moisture and weathering in use.

Benefits

Performance

Many of the benefits observed in Accoya® solid acetylated wood, including enhanced dimensional stability, durability and fungal resistance, hold true for Tricoya®. The functionality and versatility of wood-based composite panels give them universal appeal. Up until this point, the suitability of MDF panels for exterior and indoor constant wet use environments has been limited and over laid with practical limitations.

Tricoya® combines the versatility, ease of machining, ease of coating and large panel format with the performance heritage and credentials of Accoya®. Accoya® and Tricoya® have been in the European market since 2007 and 2011 respectively. In New Zealand, Accoya® and Tricoya® have been in the market and used continuously since 2010 and 2014 respectively. The products are living up to the promise for cabinet makers, shopfitters, manufacturers and specifiers alike.

We encourage you to take a Tricoya® sample, cut it, drill it, soak it and bury it. The panel performs.